Fractionation trays including sieve round valve rectangular valve. Their design is an essential part of a process engineers task and determines the process reliability and economy.

Distillation Column Column Internals Bubble Cap Trays Valve Trays Sieve Trays Structured Packing

What we have 12 tray bubble-cap distillation column Isoproply alcohol water separation What we want Same distillation column Ethanol water separation How to get there Operate column at total reflux Determine stage efficiency Model the column in Aspen Compare Aspen model to real IPA separation results Apply the Aspen model to an Ethanol.

. The trays were numbered in descending order with the top tray designated tray 1. Bubble-cap Distillation Column Design Guidelines wwwmsubbuin Column Sizing An estimate of the overall column size can be made once the number of real stages required for the separation is known. A distillation column will be an integral part of the proposed process.

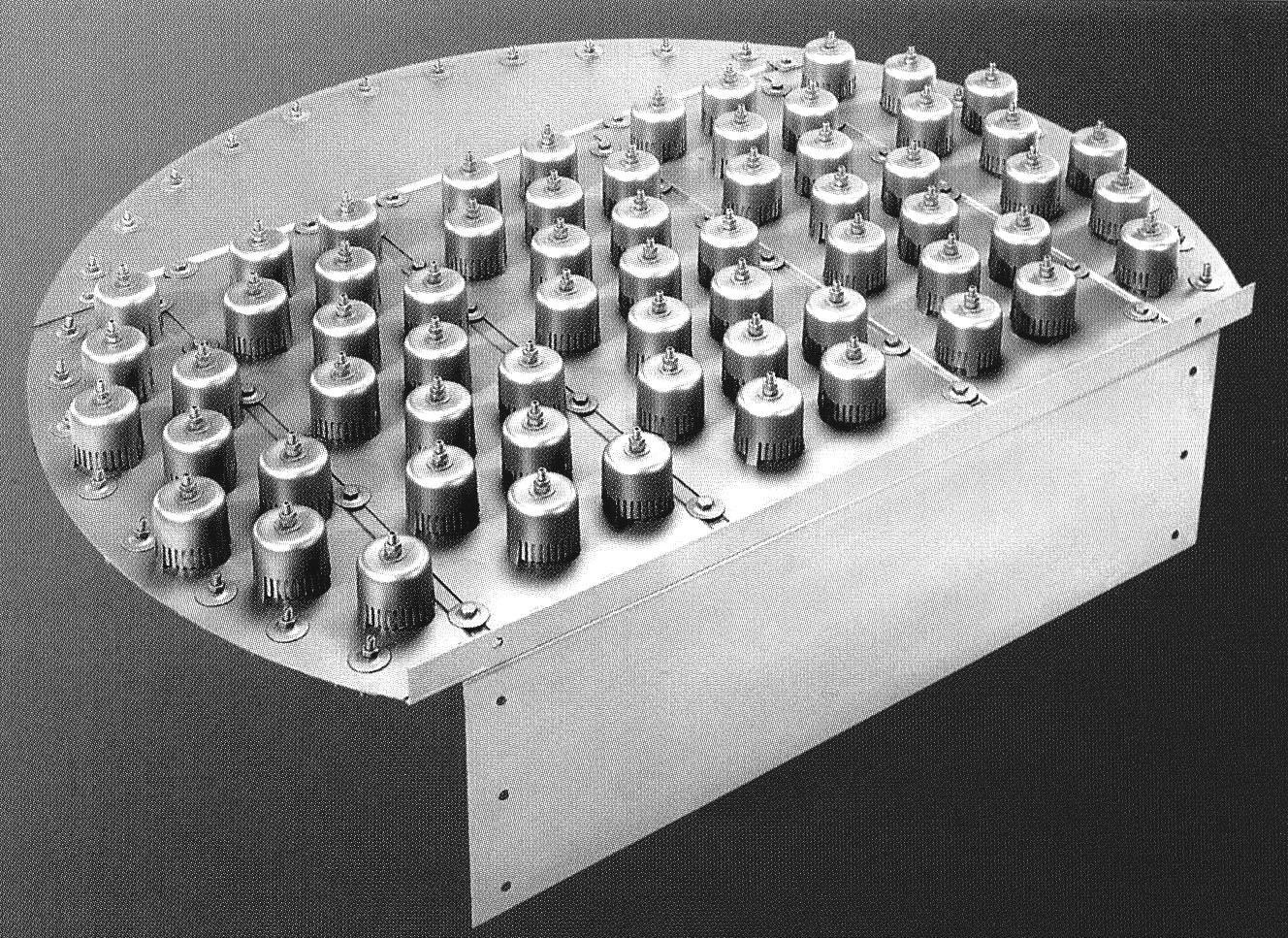

MTL can manufacture and supply you with all sizes of bubble caps and assemblies from 2 up through 6. Our design is going to rely on empirical. The bubble-caps were 3 in diameter with square openings.

There are still many bubble-cap columns in use and the design considerations presented in Volume 6 are given to enable in particular existing equipment to be assessed for new applications and duties. Bellow is discussed each type. This distillation column will make use of bubble cap trays to effect vapor-liquid contact.

Each tray in a distillation column is designed to promote contact between the vapor and liquid on the. Bubble Cap Tray Distillation Column Design. The bubble cap tray is still a good fit and widely employed.

The distillation column contained 12 bubble cap trays spaced at 11 intervals. Hellow allThis is my first enginnering assignment to suggest modification in tray design. Plate spacings from 015 m 6 in to 1 m 36 in are normally used.

Where is the number of actual physical plates or trays is the number of theoretical plates or trays and is the plate or tray efficiency. Column diameter which determines the through-put. Examples of common packing that were used in industries are packed column and bubble cap.

We have little experience in the design of distillation columns and even less experimental data. This article is the 2nd part of a series on different kinds of trays and. MTL specializes in the manufacturing of all types of replacement.

Large if froth is expected also allow space for crawling 12 to 24. Regardless of the OEM we can manufacture most kinds of trays in any type of metallurgy from Carbon Steel to Hastelloy B-3 without sacrificing reliability or quality. Turndown a term for the decrease of efficiency due to low tray vapor velocity is important to consider when using heat integrated distillation columns The images below show a sieve tray.

The company has little experience in the design of distillation columns and even less experimental data. But each distillation column will used different type of packing. Bubble cap tray design calculation For more support Its also possible to check out guidelines and guides in other on line meansTokyo Samurai is likewise a good selection even though it requires a subscription from you.

Fluid velocity larger than ascending bubbles minimum width. Plate spacing The overall height of the column will depend on the plate spacing. And bubble cap trays just to name a few.

Bubble cap trays are capable of dealing with very low liquid rates and are therefore useful for operation at low reflux ratios. Page 15 of 50 Kolmetz Handbook KLM Technology Of Process Equipment Design Group Rev. There were other type of pack or tray such as pro-pakheli- pakceramicsaddleswire mesh and specialized structured packing.

There are five major types of tray column. This distillation column will make use of bubble cap trays to effect vapor-liquid contact. Bubble cap tray sieve deck tray dual flow tray valve tray and baffle tray.

A distillation column will be an integral part of the proposed process. Bubble Cap trays also remain as an excellent defense mechanism against fouling. This distillation column will make use of either bubble cap trays or sieve trays to affect vapor-liquid contact.

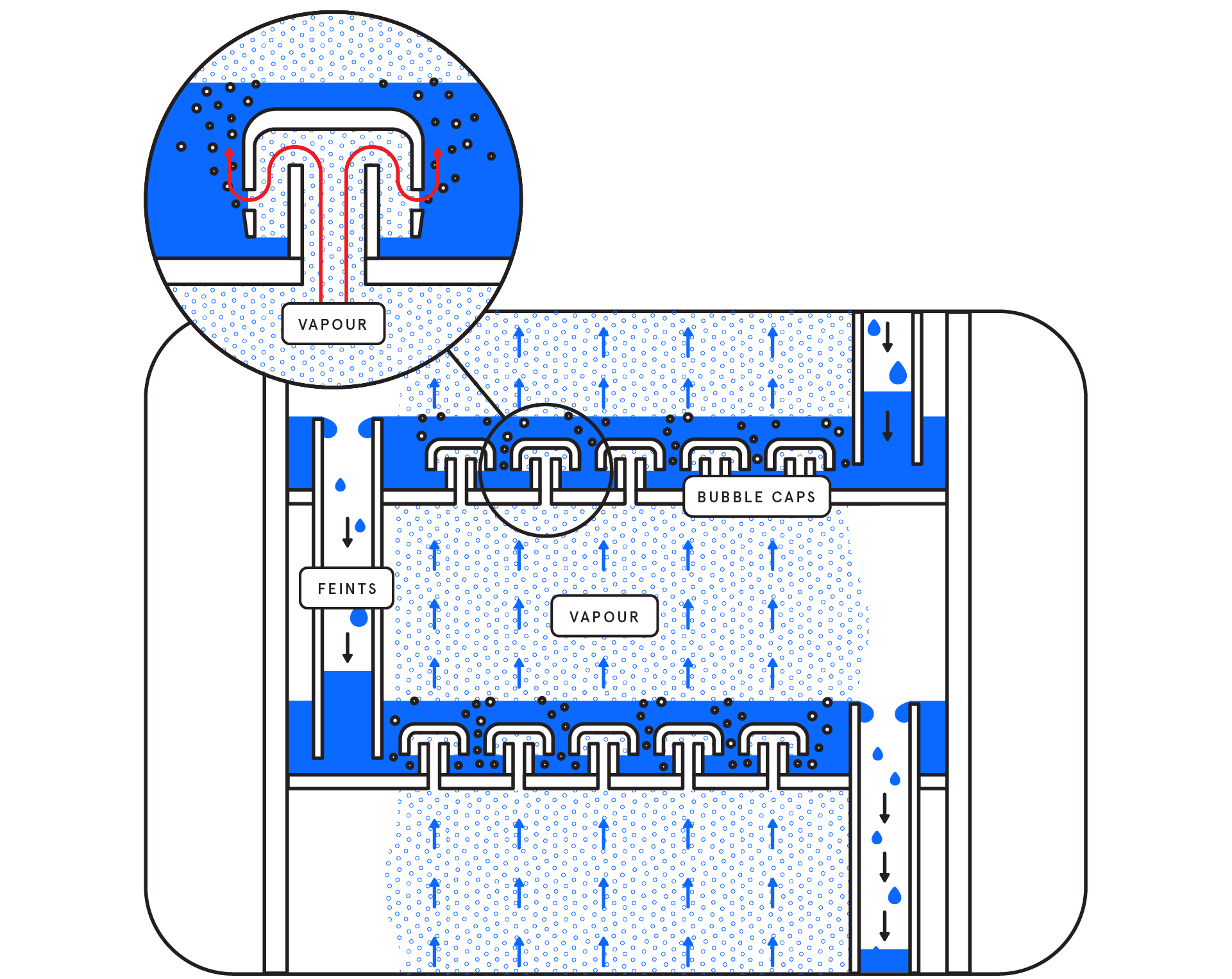

The total column height was 145. The cap column divert the vapor flow below the level of liquid on the tray deck where it is jetted into the liquid either through slots at the bottom of the cap or else between the skirt of the cap and the tray deck. The cost of a tray column is determined by two factors.

5 Range of velocities 01-07 ftsec. As we know they are costly than sieve or valve trays but the they possese good turndown which is important for usI am not getting from. Hence the design is going to rely on empirical correlations available in the literature.

The picture on the left is a photograph of a section of a pilot scale column equiped with bubble capped trays. Tower trays and internals are the heart of all distillation columns. The design of trays depends on the density the rate of vapor and liquid through the tray.

The tops of the 4 bubble caps on the tray can just be seen. Conventionally we are using Bubble cap trays. A bubble cap tray has riser or chimney fitted over each hole and a cap that covers the riser.

Our design is going to rely on empirical correlations available in the literature. Distillation Bubble Cap Tray Design - posted in Chemical Process Simulation. So-called bubble-cap or valve-cap trays are examples of the vapor and liquid contact devices used in industrial distillation columns.

Bubble Cap Trays feature a riser with a cap on top allowing the vapor to flow through the rise and around the cap coming into contact with the liquid as it. Residence time criteria 3-5 sec. Valve and bubble cap trays provided critical perfor-mance data are available.

Bubble cap tray distillation column design Valentines Working day is approaching it is just a month absent but There are many of stuff to arrange from dresses towards the ingesting put from bouquets towards the items baskets We have now to rearrange almost everything for our family members. Bubble Cap Column is a bell shaped cap which is fixed on the top of a cylindrical risers through which the vapor passes the tray deck. 01 Practical Engineering Distillation Column Tray Hydraulics Guidelines for Processing Plant Selection Sizing Solutions and Troubleshooting Feb 2011 ENGINEERING DESIGN GUIDELINES DEFINITIONS Active Area or Bubble Area - the deck area of the tray which may.

The cap is mounted so that there is a space between riser and cap to allow the passage of vapour. We have little experience in the design of distillation columns and even less experimental data. Each method of distillation have their own benefits to the process.

The down- comer in this case is a pipe and is shown on the right. Bubble Cap Tray The oldest widely used equilibrium-stage plate is the bubble cap tray. Bubble cap trays use the tea cup style in industry today.

Turndown ratios up to 201 can be achieved as well with a proper tray design and construction. A bubble cap tray is perforated flat plate which has a riser chimney over the holes covered with a cap. Bubble Cap Tray Design Calculation.

Each tray had a diameter of approximately 14 and contained 18 bubble-caps.

Plant Operations Bubble Cap Trays

Bubble Cap Tray Distillation Columns Mtl

Distillation Column Column Internals Bubble Cap Trays Valve Trays Sieve Trays Structured Packing

Distillation Column Column Internals Bubble Cap Trays Valve Trays Sieve Trays Structured Packing

Distillation Column With Bubble Cap Trays Download Scientific Diagram

Distillation Column Column Internals Bubble Cap Trays Valve Trays Sieve Trays Structured Packing

0 comments

Post a Comment